QHSE

Right

|

QHSE Right |

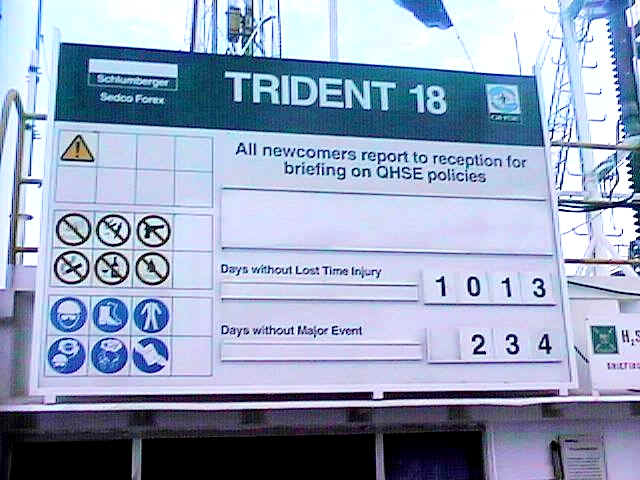

| During our

visit to the Trident 18, to capture graphic offshore scenarios for this

training package, we were impressed by the Trident-18 safety record of

1000+ days without a lost time accident, It is obvious that

their outstanding safety record was achieved because of their high safety

and quality standards which are clearly visible in daily operations.

We would like to share a few of our observations with you, in hopes that it will give you some ideas and inspiration about what can be achieved on your rig. |

|

|

As the chopper descended down to the Trident 18 we noticed the bright, white protective canopies over the port and stbd lifeboats, which we had never seen seen on any other offshore rig before. It is clear that TQM is being practiced on Trident 18. |

| Immediately upon stepping off of the Helicopter we were impressed by the clean, orderly, well painted and well maintained decks and rig structures. |  |

|

|

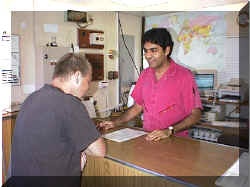

| Immediately

upon entering the Radio room to sign in, we were given one

of the Best and most informative New Arrivals Safety Briefings (click to view) which I have ever been presented, by the Rig Medic, Dr. M. Punjabi. |

|

| After being welcomed and briefed by the Rig Supt. Arnie Lacasse, we deposited our belongings in our assigned cabin, and headed outside to explore the decks and underdecks of the rig. |

| The first impressive

safety discovery on our tour were 3 maintenance roustabouts preparing to

work in a preload tank, doing chipping and painting. These guys were

following the companies Confined Space Entry Procedures to the letter.

Do Tank Entry

|

|

|

Confined Space Entry - Tank Entry Permit

|

|

|

- Fall Arrestor

- Safety Harness worn while entering & working inside tank - Tripod and

|

|

|

-Explosion

proof junction box

- Explosion Proof Lighting - Air hose manifold with air filter / lubricator - Air Ventilation Inlet - Air Ventilation Outlet |

|

|

- Safety "Whip

Chek"

and Safety Pinson - Air Hose Connections - Preload Fill Valve Locked

- Walkie in water-proof case

|

|

|

to working safely, following all policies and procedures, and producing quality workmanship. WHAT A TEAM, HUH ? We were assured by several

service hands

|

|

|

|

||

Two Daily Pre-tour Safety Meetings are held at 1115 and 2315 hr and last for 10-15 minutes. |

At

the Trident 18 Daily

Pre-tour Safety Meeting each department head, including Co. Man and service hands gives a brief summary of the work scope for the next 12 hours, with special attention given to safety. This allows clear lines of communication between everyone working on Trident 18, and creates a strong Safety Attitude and sense of team spirit |

It is Attended by

|

Whip Chek and safety pins on all air hoses |

Eye protection available where required |

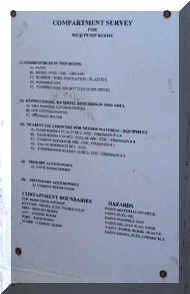

Compartment Survey at entrance to each compartment |

Realistic Training during Fire Drills |

Well organized and orderly drills |

Strict Lock-Out Procedures to prevent deadly mistakes |

permanently installed safety harness at each Lifeboat. |

Lifeboat Crew assignment Sheet |

a clean, tidy platform, clean BOP with work platforms & fall arrestors |

Hazards routinely barricaded with barrier warning tape |

Preload tanks hatches covered with safety mesh cover and clearly labeled |

Tank vents, valves, ventilation ducts, etc. clearly stenciled |

Emergency Response equipment well maintained |

Pinch points labeled with warning Crocodile stickers |

PPE policies followed and enforced by all, including supervisors. |

Authorized Forklift operator list attached to the Forklift |

STOP is actively promoted & practiced by all rig personnel |

A Weekly Stop Observer is selected and recognized |

High pressure mud hose area cordoned off with plastic chain and warning signs |

A serious TQM program with a Quality Improvement White Board in change room for crewmen's ideas |

Safety Posters in wooden frames hung in hallways, and common areas. |

Safety Net on the crane boom for performing maintenance tasks |

A safety Net over the cement room hatch |

State of the Art High Speed Rescue Boat |

An Experienced safety conscious Crew |

One Fine Rig |

Taking Pride in Tr18 |

And the Visible,

Tangible, Leadership and Commitment to Q-HSE

|

||

|

We are convinced that all of these noteworthy Q-HSE Standards are For Real and not merely a temporary Showcase staged for our visit. We'd like to offer our sincere Thanks to the Entire Trident 18 Crew for their hospitality, assistance, creative ideas and inspiration while we were onboard developing this training package.

And we commend the entire Trident 18

crew for your 1000+ days

|